STVS COATING SYSTEMS

Advanced Protective Coatings for Steel Structures

- At STVS, we deliver high-performance coating systems designed to extend product lifespan and provide durable, long-lasting protection across a variety of environmental conditions—from industrial and marine to residential and infrastructure applications.

Our innovative coating solutions meet international standards and are ideal for:

-

Modular fencing.

-

Structural steel.

-

Marine-grade environments.

-

Industrial infrastructure.

-

Outdoor and indoor applications.

1. ENVIRONMENT TYPES :

- The speed of corrosion is different in different base environments in which it is located.

- Weather condition/ Atmospheric corrosivity according to EN ISO 12944-2 standard.

Catergory

Exterior

Interior

C1

Very low- Dry, clean evironments.

Offices, schools, hotels.

C2

Rural areas, >20 km from sea.

Unheated storage facilities (storage facilities, halls).

C3

Industrial/inshore, low salinity, >20 km from sea.

Production halls to facilities (Breweries, dairies, laundries).

C4

Industrial areas and inshore areas of medium salinity, from 3–20 km to the sea side.

Chemical plants (swimming pools, ship yards).

C5

Industrial areas of high humidity and aggressive atmosphere, from 500 m–3 km to the sea side.

Areas of almost constant condensation and high contamination.

CX

Offshore areas of high salinity or industrial areas of extremely high humidity, <500 m to the sea.

Buildings and areas of almost constant condensation and aggressive contamination.

2. STVS ADVANCED PROTECTION SYSTEMS:

- The speed of corrosion is different in different base environments in which it is located.

- Weather condition/ Atmospheric corrosivity according EN ISO 12944-2 standard:

Catergory

Description

Recommend application

G1

Powder coating paint 1 layer on galvanized steel

Indoor and outdoor application for C2→C3 environment

G2

Powder coating paint 2 layer on galvanized steel

Indoor and outdoor application for C2→C5 environment

HDG

Hot dip galvanized according to ASTM A123 standard

Indoor and outdoor application for C2→C5 environment

G3

2 layers liquid paint

Indoor and outdoor application for C2→C3 environment

G4

(STVS MARINE COATING)

4 layers liquid paint (STVS MARINE COATING)

Indoor and outdoor application for C2→C5 environment

G5

(STVS MARINE COATING for CX)

Hot dip galvanized + 3 layers liquid paint (CX)

Indoor and outdoor application for C2→CX environment

3. WHY CHOOSE STVS COATING SYSTEMS:

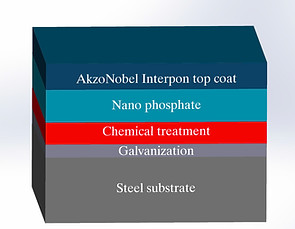

MULTI-LAYER PROTECTIVE SYSTEM:

- Combine primer, basecoat, and topcoat into a durable multi-layer structure.

- This method significantly enhances surface strength and corrosion resistance.

- Extend your product’s lifespan up to 10 years while reducing repainting costs and operational downtime.

HIGH CORROSION RESISTANCE:

- STVS coatings are specially formulated to endure harsh environments, including coastal salt air, industrial zones, and humid climates.

- They ensure reliable, rust-free performance even in the most demanding conditions.

- Long-term protection you can trust—ideal for outdoor, marine, and factory applications.

ECO-FRIENDLY, SOLVENT-FREE TECHNOLOGY:

- We use environmentally responsible, solvent-free coating systems that comply with international standards.

- Our solutions are safe for workers and reduce your project’s environmental footprint.

- Meet green building certification requirements while promoting sustainability.

UV AND WEATHER RESISTANCE:

- Our coatings are built to withstand sunlight, rain, humidity, and temperature changes.

- They prevent color fading, chalking, and surface deterioration over time.

- Keep your surfaces vibrant and professional-looking for years—enhancing your brand image and structural appearance.

4. COATING SPECIFICATION:

POWDER COATING

COATING NAME

G1

G2

Layers detail

Type

Powder Coating

Powder Coating

Steel Surface

Galvanized steel

Galvanized steel

Surface Preparation

Auto-line chemical treatment + Nano phosphate

Auto-line chemical treatment + Nano phosphate

Primer Layer

- Epoxy Primer for C2→C4

- Zinc-Epoxy Primer for C5

Top Coat

AkzoNobel Polyester Powder Coating

AkzoNobel Polyester Powder Coating

Thickness

70-120µm

120-240µm

Corrosion Resistance

Good

Superior

UV Resistance

High

High

Adhesion

Superior

Superior

Color

Standard Colors

Customize with MOQ 1000m²

Standard Colors

Customize with MOQ 1000m²

Applications

C2→C3

C2→C5

Warranty

10 years corrosion protection

10 years corrosion protection

LIQUID COATING

COATING NAME

G3

G4

(STVS MARINE COATING)

G5

(STVS MARINE COATING for CX)

Layers detail

Type

Liquid Paint System

Liquid Paint System

Liquid Paint System

Steel Surface

Mild Steel

Mild Steel

Hot dip galvanization

Surface Preparation

Shot Blasting SA2.5

Shot Blasting SA2.5

SSPC-SP16 / Light blasting

Primer Layer

PPG Epoxy Primer

Epoxy Primer: C2→C4

High Zinc Primer: C5

PPG Epoxy Primer

Mid Layer

PPG Epoxy Primer

PPG Epoxy Primer

Top Coat

Jotun Hardtop AX Top-Coat

Jotun Hardtop AX Top-Coat

Jotun Hardtop AX Top-Coat + Clear Coating

Thickness

100–120µm

240–350µm

200–250µm

Corrosion Resistance

Good

Superior

Superior

UV Resistance

Good

Good

Good

Adhesion

Superior

Superior

Superior

Color

Flexible Colors

Flexible Colors

Flexible Colors

Applications

C2→C3

C2→C5

C2→CX

Warranty

05 years corrosion protection

10 years corrosion protection

10 years corrosion protection

5. WARRANTY MATRIX:

*Warranty in years

.png)

-

Warranty matrix apply for steel material.

-

The tolerances applicable to the anti-corrosion warranty are defined in accordance with ISO 4628-3 for rust grade assessment and ISO 4628-2 for blistering evaluation.

-

Warranty does not cover damage caused by direct chemical exposure

-

For CX environment: minimum distance to the sea water is 100m.

6. OPTIMIZED SOLUTIONS FOR EVERY ENVIRONMENT:

From modular fencing and structural steel to marine and industrial-grade applications, STVS Coating Systems offer tailored protection that ensures long-term performance and aesthetic excellence. Our advanced formulations are meticulously designed to meet the most demanding environmental challenges while maintaining a professional finish.

7. COLORS:

Powder coating standard colors:

Other color upon request

8. STVS REGULAR MAINTENANCE OF ITS PRODUCTS:

-

Frequency: all surfaces require 6-monthly maintenance. Coated surfaces that are exposed to dust, mud, sand or salt require meticulous cleaning.

-

Cleaning: this involves washing with water and a mild detergent (pH 5 to 8) followed by careful rinsing with clean water and drying. The use of an abrasive cleaner is prohibited.

-

Special maintenance for motor-driven gates: maintenance is compulsory and must be performed once every 6 months. STVS offers installation services as well as maintenance and servicing agreements. Contact STVS or our subsidiary.

9. CONDITION OF WARRANTY :

-

STVS grants a 2-year operation warranty that is activated upon the actual start-up of the product or within a maximum of 2 years of delivery of the product.

-

The warranty applies to the initial installation site subject to products being maintained each 6 months as maintenance recommendations.

-

Wear parts (pinions, racks, batteries, rollers, etc.) are not covered by the warranty.

-

Corrosion warranty are not applied for accessories parts.

-

Minimum distant to the sea site 100m for CX environment .